Our Manufacturing Processes

Precision manufacturing excellence through advanced processes and cutting-edge technology

Our Core Capabilities

Three specialized divisions working in perfect harmony

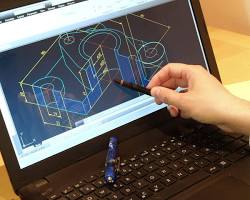

Tool Room

Design, Make Die sets, maintenance of dies, develop tools, jigs and fixtures for different applications

Foundry/Casting

Pressure Die castings and initial casting operations

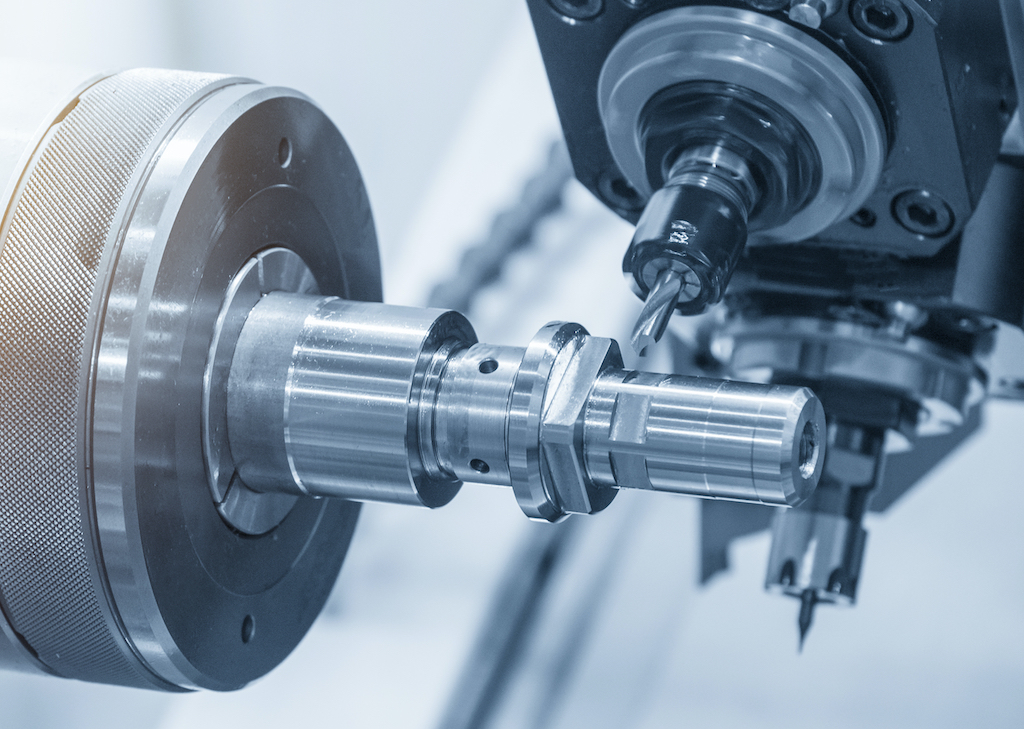

Machine Shop

Machining of components as per drawing or samples

Manufacturing Process Flow

From design to delivery - our complete manufacturing journey

Die Design/Develop Die Set

Creating precise die designs and developing complete die sets for production

Pressure Die Casting & Heat Treatment

High-pressure metal casting process with integrated heat treatment for optimal material properties and precision components

Machining

Precision machining of cast components to exact specifications

Multi Tooling/Multi Spindle Machines

Advanced multi-tooling operations for complex component manufacturing

Inspection / Testing

Comprehensive quality control and testing of finished components

Packaging

Secure packaging of finished components for safe transportation

Dispatch

Final dispatch of packaged components to customers